Dynamic Pass Box

- Home Dynamic Pass Box

Dynamic Pass Box Manufacturers in Pune, Suppliers and Dealers in Pune

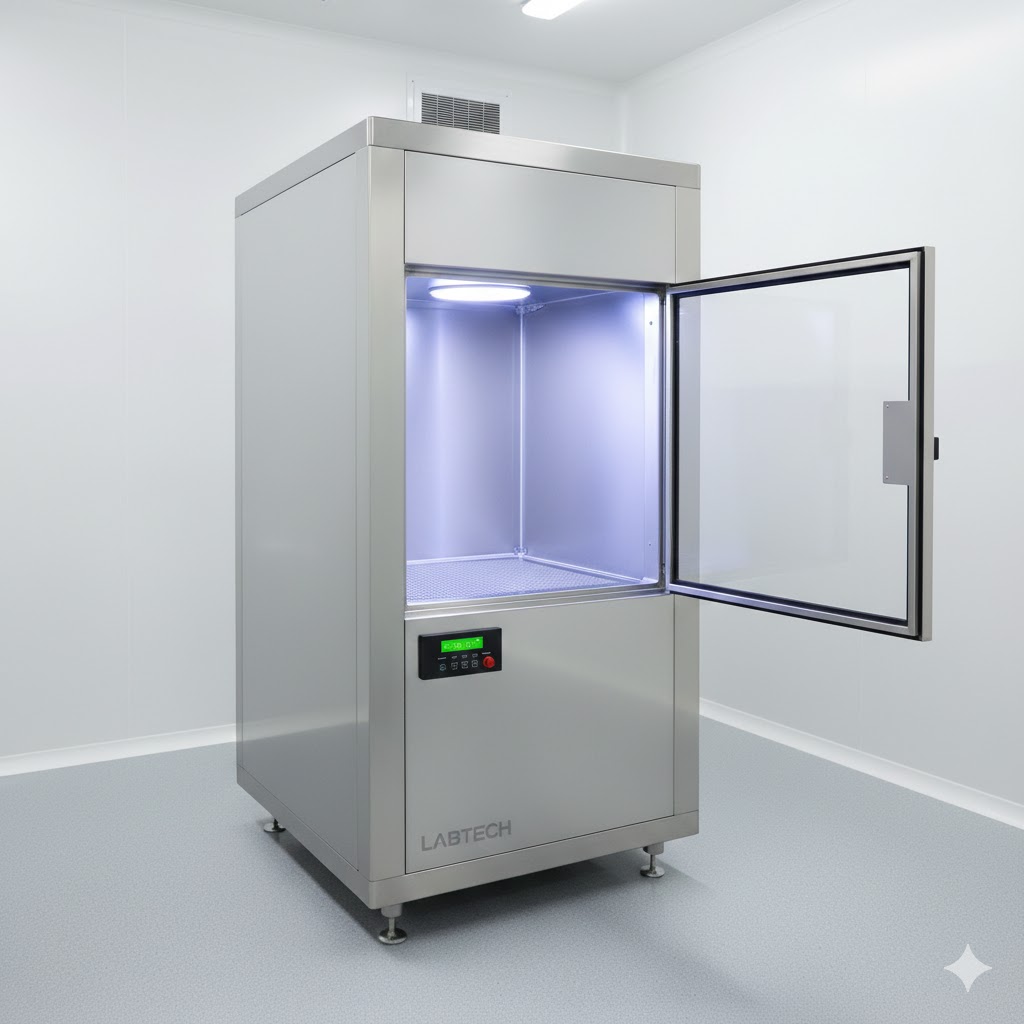

National Air Filters is leading Dynamic Pass Box Manufacturers in Pune, Suppliers, Dealers in Pune. Being one of top products in our contamination control line, it actively stops cross-contamination between the zones of different levels of cleanliness. The DPB has an internal air circulation system which is HEPA-filtered, and which actively scrubs the material passing through it, before it enters a sterile environment and is determined to contain no airborne particulates. Its strong construction and interlocking system is such that it is indispensable in the sensitive industries.

Where to use Dynamic Pass Box?

Designing purified and high-velocity air flows across materials within the interior will also result in an air-purged environment. This is done to eliminate the surface particles and the materials are clean when they get to the sterile environment. The system is essential in the conditions when it is critical to avoid ingress of particles and keep the air pressure controlled to secure the integrity of the product and comply with the regulations.

Why we notable as Dynamic Pass Box Manufacturers in Pune?

Our uncompromising approach to precision engineering and compliance has enabled us to be ranked as one of the best suppliers of Dynamic Pass Boxes in Pune in terms of high performance in the filtration process in line with the strict industry standards such as ISO and GMP. Our Pune plant is equipped with the latest production processes and quality checks on each unit.

Types of Dynamic Pass Box

We being as prominent dynamic pass box manufacturers in Pune, according to area we provided different types which are given below.

- Cleanroom dynamic pass box: A transfer chamber that is a sealed transfer chamber utilizing active filtered air (fan/HEPA) in order to reduce the transfer of particles between cleanroom areas or a clean room with a less clean area.

- Dynamic pass box controller: A dynamic pass box electronic interface and logic unit that controls the blower, interlock, UV light, and cycle time of a pass box.

- SS Pass box: Pass box A pass box is a stainless steel (typically SS 304 or SS 316) pass box made of stainless steel to be durable and easy to clean in dynamic pass box suppliers in Pune.

- Static pass box: This is an uncomplicated and non-electrified transfer chamber featuring two doors and is dependent on the interlock mechanism to ensure that both doors are not opened at the same time.

- Dynamic pass box with double door: This is a type of dynamic pass box that incorporates an interlocked door on both sides to allow the transfer of material when the internal fan/HEPA unit is operating a cleaning cycle.

- SS 304 dynamic pass box: A dynamic pass box which is specially manufactured with Grade 304 stainless steel, that has good corrosion resistance and can be used in most of the clean room applications.

Technical Specifications of Dynamic Pass Box

We've added below a specialized table of Dynamic Pass Box in Pune that provides further technical specification information.

| Feature/Specification | Value |

|---|---|

| Material | Stainless Steel / Powder-coated Sheet Metal |

| Air Filtration | HEPA Filter with Fan Unit |

| Door Type | Interlocked Swing Doors |

| Size | Customizable as per requirement |

| Usage/Application | Cleanroom / Laboratory Material Transfer |

| Air Velocity | 0.3 - 0.5 m/s laminar airflow |

| Lighting | Integrated LED light |

| Maintenance | Easy filter replacement and cleaning |

| Lifespan | Long-lasting with proper care |

Key Features of Pass Box in Industry dynamics.

We serve as prominent dynamic pass box suppliers in Pune, we provided different key features which are given below.

- Active Contamination Removal: The incorporated HEPA filtration system establishes the directionality of the clean air in the chamber. This air jet is actively used to scrub off the surface of the transferred materials in dynamic pass box manufacturers in Pune.

- Blocks Cross-Contamination: The essence of this is that the doors have an electromagnetic interlocking mechanism. This safety measure provides the physical isolation of the two environments such that neither of the two doors can be opened at the same time.

- Ensures Room Pressure Integrity: The DPB reduces air pressure variability and inhibits a large amount of air flow between the clean and non-clean sections of the room due to dynamic pass box dealers in Pune performance as an airlock.

- High Cleanliness Standard (ISO Class 5): The DPB is designed in such a way that it obtains high-level air cleanness (usually Class 100/ ISO 5) in the transfer chamber. This is to guarantee the process of material transfer per se is not contaminated with novel contamination.

Applications of Dynamic Pass Box dealers in Pune

- Pharmaceutical Manufacturers: This is to be used to move raw materials, intermediates and products into classified areas without interference with the ISO Class 5 quality of the air. This eliminates cross-contamination of batches of drugs and ensures sterility.

- Hospitals and Healthcare: Necessary in operation theaters, intensive care units and isolation wards to transfer medical supplies safely as well as prevent microbial penetration into critical patient zones in Active Pass Box.

- Food & Nutraceutical Processing: Ensures the transfer of material between the standard and controlled processing areas is hygienic of ingredients, packaging and tools. It shields fragile consumables against contamination by dust and microbes.

- Biotechnology and Research Labs: Of critical importance in the transportation of samples, media and equipment into sterile culture rooms or laboratory settings. The filtered air keeps out the contamination which may spoil delicate experiments.

- Electronics and Semiconductor Industry: To transfer delicate components and wafers to ultra-clean assembly zones. It makes sure that the components are free of micro -particles that may lead to disastrous breakdown of complex electronics.

Process of selecting a Dynamic Pass Box

- Determine Cleanliness Requirement: Identify a DPB that matches the needed ISO cleanliness classification (e.g., Class 100/ ISO 5) in your process in dynamic pass box manufacturers in Pune.

- Verify Material of Construction (MOC): Since MOC (usually SS 304 or SS 316) will be used, make sure that it is of proper sanitation and chemical resistance to your industry.

- Check Filtration Specifications: Find certified HEPA filters (H14 grade, 99.997% efficiency) and an appropriate pre-filter to allow longer filter life.

- Confirm Interlocking System Reliability: The door interlocking mechanism should be strong and fail-safe and preferably electromagnetic to guarantee the reliability of cross-contamination.

Why Customers prefer us as dynamic pass box suppliers in Pune?

- Established Quality and Certification: We have been complying with international quality standards (ISO/GMP) which gives fully verified units offering uniform performance and conformity.

- Customization Skills: we are experts of designing and making customized DPB sizes and features to perfectly fit in special cleanroom designs.

- Localized After-Sales Service: Our after sales team will also be able to give you all-inclusive installation, testing and maintenance services within the Pune locality.

National Air Filters is foremost dynamic pass box manufacturers in Pune, suppliers, dealers in Pune and actively purifies materials with ISO Class 5 HEPA-filtered air, so that there is no cross-contamination in the transfer. The fail-safe mechanism and SS construction that is GMP-approved ensures maximum product security and regulatory compliance. Select the familiar local leader with accuracy, high performance and loyal service. Get your transfer process secure today. Contact now!

FAQ's

A: Dynamic Pass Box is a cleanroom equipment used to safely transfer materials between two controlled areas. It maintains air cleanliness and pressure balance, helping prevent cross-contamination in pharmaceutical and cleanroom environments..

A: Yes. Our Dynamic Pass Boxes are designed to meet GMP and cleanroom standards, ensuring contamination control and regulatory compliance for pharmaceutical manufacturing units.

A: Absolutely. We offer customized Dynamic Pass Boxes based on size, stainless steel grade (SS 304 / SS 316), HEPA filter efficiency, airflow design, and specific application requirements.

Our Products